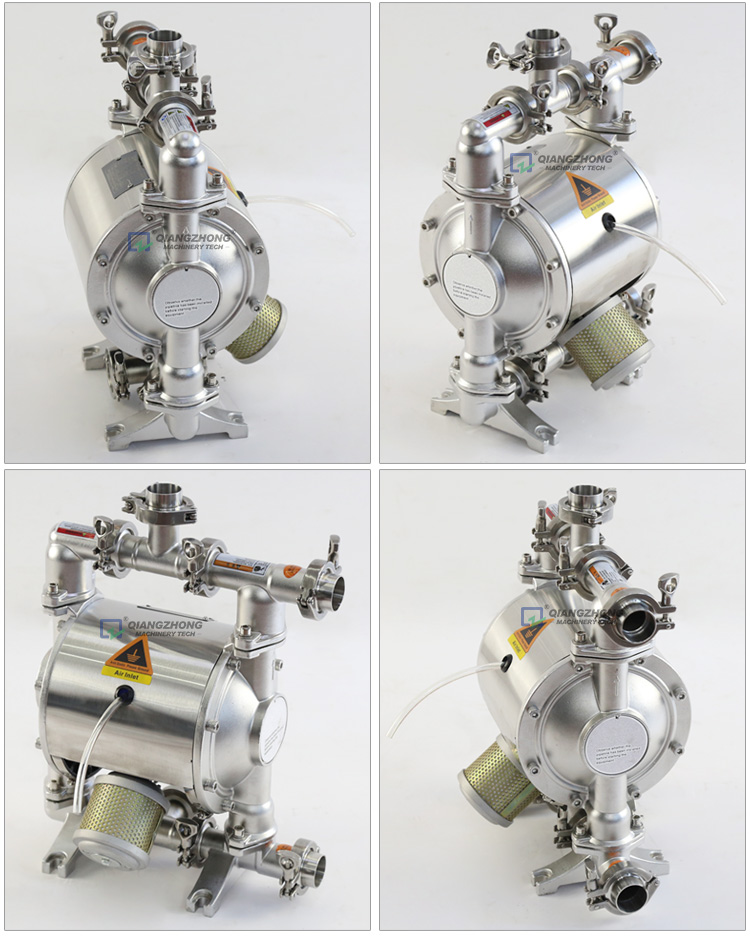

Sanitary Pneumatic uvalo Pump

Isetyenziswa kwizihlandlo ezahlukileyo ezizodwa ukuhlangabezana neemfuno zabasebenzisi abahlukeneyo Isetyenziselwa ukumpompa imithombo yeendaba engenakho ukupompa iimpompo eziqhelekileyo kunye nokufumana iziphumo ezonelisayo.

Iiparamitha zeMveliso

| Umzekelo No. |

Ukuhamba (T / h) |

Dia. (mm) |

Ukuphakamisa (m) |

Ukufunxa (m) |

Ukusetyenziswa koxinzelelo lomoya oSetyenziswayo woxinzelelo. |

ubunzima (kg) |

||

|

(mpa) |

(scfm) |

(mm) | ||||||

| QBSY5-20 | 0.1-1.8 |

20 |

0-50 |

4.5 |

0.6 |

12.7 |

2.5 |

10 |

| QBSY5-25 | 0.1-1.8 | 25 | 0-50 |

4.5 |

0.6 |

12.7 |

2.5 |

10 |

| QBSY5-32 | 0.1-6 | 32 | 0-50 |

4.5 |

0.7 |

23.66 |

3.2 |

16.8 |

| QBSY5-38 | 0.1-6 | 38 | 0-50 |

4.5 |

0.7 |

23.66 |

3.2 |

16.8 |

| QBSY5-51 | 0.1-12 | 51 | 0-50 | 5.48 |

0.75 |

32 |

5.5 |

33 |

| QBSY5-63 | 0.1-12 | 63 | 0-50 | 5.48 |

0.75 |

12.7 |

5.5 |

33 |

| QBSY5-76 | 0.1-22 |

76 |

0-50 | 5.48 |

0.75 |

12.7 |

6.3 |

54 |

| QBSY5-89 | 0.1-22 |

89 |

0-50 | 5.48 |

0.75 |

12.7 |

6.3 |

54 |

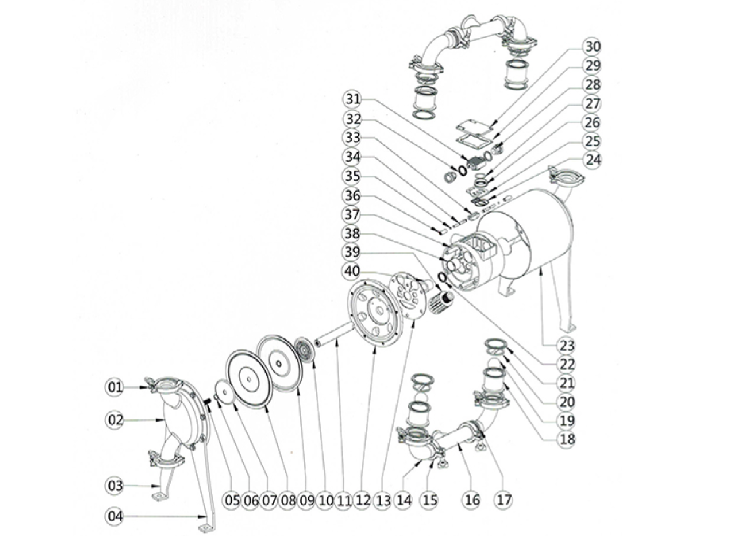

| 1. B Uhlobo loCingo | 11. Ukudibanisa iRod Shaft | 21. Uhlobo lwe-BType | 31. Izilayidi ezinkulu zeAluminiyam |

| 2. Ikholam | 12. Imiqolo | 22. V-Iringi | 32. V Isandi |

| 3. Unyawo lwaseNxele | 13. Igumbi leValve yeVafu yegesi | 23. Isikhuselo sokhuseleko | 33. Isilayidi esincinci |

| 4. Unyawo lwasekunene | 14. Ukulayisha ngokukhawuleza | 24. Isikhokelo seBasket Gasket | 34. Ukukhuthaza intonga |

| 5. Izikrufu zeplywood | 15. Uhlobo loCingo | 25. Isikhokelo seBhloko | 35. Ukunyusa iRod O-Ring |

| 6. Ukwahlula i-O-Ring | 16.Ukungenisa kunye nokuPhuma kwePayipi | 26. Iindawo ezinkulu zePlastiki zeSilayidi | 36. Ukusebenza kweRod Cover |

| 7. Uqhekezo lwangaphandle | 17. Uhlobo lokuTywina iRingi | 27. Isilayidi esikhulu se-O-Ring | 37. Igumbi leValve |

| 8. PTFE ndizayo | 18. Ibhola Valve | 28. Iipiston | 38. IPiston sleeve |

| 9. Ifilimu yePoly | 19. Ibhola Valve | 29. I-Gasket yeValve yeNqwelo yegesi | 39. Umthulisi |

| 10. Ukwahlula ngaphakathi | 20. Uqweqwe lweSihlalo seBhola | 30. Ikhava yeValve | 40. Ukudibanisa i-Rod Sleeve |

Umgaqo wokuSebenza

Impompo ye-diaphragm yomoya yimpompo yevolumetric ezisa utshintsho lwevolumu ngokuphindisela ukubuyela umva kwesithambo. Umgaqo-nkqubo osebenzayo uyafana nempompo yeplunger. Iimpompo zediaphragm zinezi zinto zilandelayo:

I -Impompo ayizukufudumala: Ngomoya oxineneyo njengamandla, i-exhaust yinkqubo yokwandisa kunye nokufunxa ubushushu, ke ngexesha lokusebenza, ubushushu bempompo buyehlisiwe kwaye akukho gesi iyingozi ekhutshiweyo.

2-Akukho sizukulwana senkunkuma: Iimpompo zedyaphragm ezinomoya womoya azisebenzisi amandla ombane njengomthombo wamandla kwaye zinokuthintela iintlantsi zombane emva kokuba zithotyelwe.

I-3.lt inokudlula kulwelo oluqulathe amasuntswana: Kuba isebenzisa indlela yokusebenza yevolumu kwaye indawo yokungena yivelufa yebhola, akukho lula ukuyivimba.

4. Amandla okucheba asezantsi kakhulu: imathiriyeli ikhutshwa ikwimeko efanayo nale xa ifunxwayo xa impompo isemsebenzini, ke ukuphazamiseka kwemathiriyeli kuncinci kwaye kufanelekile ukuhambisa izinto ezingazinzanga.

5. Inqanaba lokuhamba elinokuhlengahlengiswa: Ivalve yokujija inokufakwa kwindawo yokuphuma ukuze ulawule ukuhamba.

Umsebenzi wokuzihlaziya.

7. Inokuma ngaphandle kwengozi.

8.lt inokusebenza ngokuntywila.

9. Uluhlu lolwelo olunokuhanjiswa lubanzi kakhulu ukusuka kwi-viscosity ephantsi ukuya kwi-viscosity ephezulu, ukusuka ekubonakaliseni ukuya kwi-viscous.

10. Inkqubo yolawulo ilula kwaye ayinzima, ngaphandle kweentambo, iifyusi, njl.

II Ubungakanani obuncinci, ubunzima bokukhanya, kulula ukuhamba.

Ukuthambisa ayifuneki, ke ukugcinwa kulula kwaye akubangeli ungcoliseko lwendawo yokusebenza ngenxa yokuvuza.

13.lt inokuhlala isebenza kakuhle, kwaye ayizukunciphisa ukusebenza ngenxa yokunxiba.

I-14.100% yokusetyenziswa kwamandla. Xa iplagi ivaliwe, impompo iyema ngokuzenzekelayo ukuthintela ukuhamba kwezixhobo, ukunxiba, ukulayisha ngaphezulu kunye nokuvelisa ubushushu.

Akukho tywina linamandla, ukugcinwa kulula, ukuvuza kuthintelwe, kwaye akukho ndawo ifileyo xa usebenza.