Iiparamitha zeMveliso

Intshayelelo yeMveliso

Impompo yokujija ifunxa kwaye ikhuphe ulwelo ngokusebenzisa ukujikeleza kwescrew. Isikrufu esiphakathi sisixhobo esisebenzayo, esiqhutywa sisishukumisi sokuqala. Izikere kumacala omabini zizikere eziqhutywa, kwaye zijikeleza zijike ngesikere esisebenzayo. Zombini ezi zinto zisebenzayo kunye neziqhutywa yimisonto yokujija ziphela kabini. Ngenxa yokungena phakathi kokujikeleza kunye nokulingana kokujikeleza komoya kunye nodonga lwangaphakathi lwe-liner, uthotho lwezithuba ezitywiniweyo ezininzi zenziwa phakathi kwendawo yokutsala kunye nokuphuma kwempompo. Ngokujikeleza kunye nokuzibandakanya kwesikrufu, indawo yokutywina eqhubekayo yenziwa kwisiphelo sokumpompa, ulwelo kwigumbi lokufunxa litywinwe kulo, kwaye lityhalelwa ngokuqhubekayo kwigumbi lokutsala ukuya esiphelweni sokuphuma kwicala lokujikeleza le-axial . Iyaqhubeka kwaye ikhuphe ngokukuko ulwelo oluvalelwe kwizithuba ezahlukileyo, ngokungathi amandongomane aqhubekeka ngokuqhubekeka phambili ngelixa ujikelezayo. Lo ngumgaqo osisiseko osebenzayo kolu ngcelele lwempompo yokujija kabini.

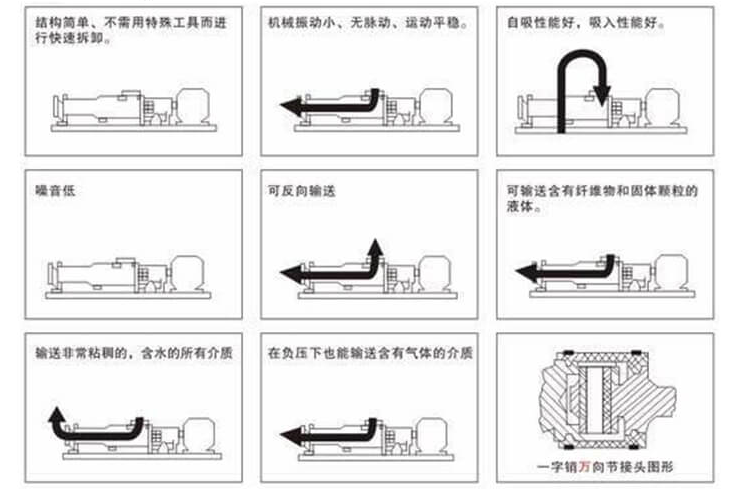

Iimpawu zePompo zeScrew:

Umgca wokutywina ojikelezayo ngokudibana ne-stator ye-stator ukwahlula ngokupheleleyo igumbi lokutsala kwigumbi lokukhupha, ukuze impompo isebenze ngokufana nevalve;

Inokuhambisa imithombo yeendaba yezigaba ezininzi zolwelo, igesi kunye nokuqina

Umthamo awuguquki xa ulwelo olukumpompo luhamba, akukho siphithiphithi sishukumisayo kunye nepulsation;

Igumbi levolumu elenziwe yi-stator e-elastic linokunciphisa ngokufanelekileyo ukuwohloka okuphakathi okuqulathe amasuntswana aqinileyo;

5.Igalelo le-viscosity ephakathi ukuya kuthi ga kwi-50: 000Mpa s, eziqinileyo ukuya kuthi ga kwi-50%;

6.Ireyithi yokuhamba ilingana nesantya, kwaye nerhuluneli, inokulungelelanisa ngokuzenzekelayo ukuhamba kwayo, kwaye zombini ukuhambisa nokubuyela umva kuvunyelwe.

Impompo Screw ine ezi zinto zilandelayo:

• Xa kuthelekiswa nempompo ye-centrifugal, impompo yesikere ayifuni ukufaka ivalve, kwaye ukuhamba kwe-r kutya kukuhamba komgama okuzinzileyo;

• Xa kuthelekiswa nempompo yeplunger, impompo yokujijisa inamandla okuzimela kunye nokuphakama okuphezulu kokutsala;

• Xa kuthelekiswa nempompo yedayaphragm, impompo yokujija inokuhambisa zonke iintlobo zobumdaka obuxubeneyo, ezinje ngegesi ephakathi kunye namasuntswana aqinileyo okanye imicu, kwaye inokuhambisa izinto ezinobungozi;

• Xa kuthelekiswa neempompo zegesi, iimpompo zokujija zinokuhambisa imithombo yeendaba ebonakalayo;

• Ngokungafaniyo neepiston pumps, diaphragm pumps and gear pumps, screw screws can be used to filling and metering pharmaceuticals.

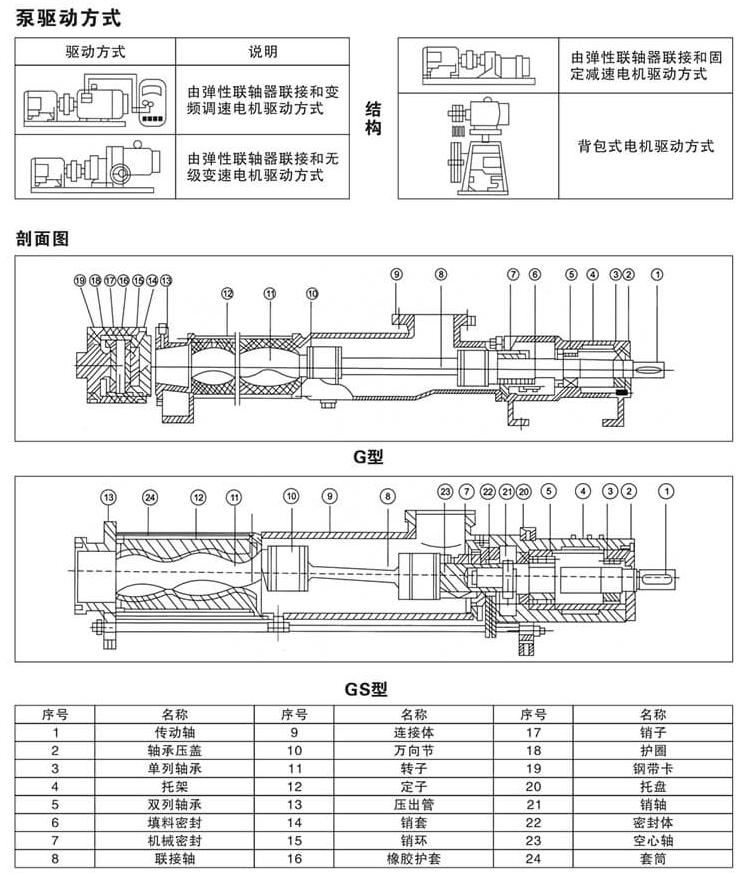

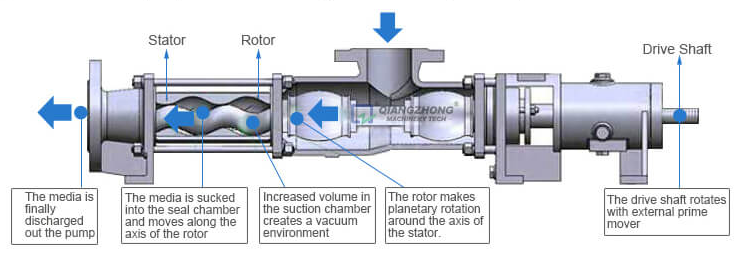

Umgaqo wokuSebenza

Impompo yokujija yimpompo yohlobo lokufuduswa. Izinto eziphambili ziyi-rotor kunye ne-stator. I-Rotor isikhokelo esikhulu, esinamazinyo amakhulu, kunye ne-screw-encinci ye-helix yangaphakathi, kwaye i-stator ifanelana neentloko ezimbini kunye ne-sleeve, eyenza indawo yokugcina phakathi kwe-Rotator kunye ne-stator . Xa iRoror isebenza kwi-stator, eliphakathi lihamba ngokuthe ngcembe ukusuka kwisiphelo sokutsala ukuya kunyango lokukhupha.

Impompo Screw ine ezi zinto zilandelayo:

Mna. Uluhlu olubanzi loxinzelelo kunye nokuhamba. Uxinzelelo lumalunga ne-3.4-340 kgf / cm2 kwaye inqanaba lokuhamba li-1,8600 cm3 / m;

Uluhlu olubanzi lweentlobo kunye ne-viscosities yolwelo olunokuhanjiswa;

I-3.Inejubane eliphezulu ngenxa yamandla asezantsi e-inertia eendawo ezijikelezayo kwimpompo

4.Ngamandla okuzimela, ukusebenza kakuhle,

Ukuhamba okungafaniyo, ukungcangcazela okuphantsi, ingxolo ephantsi;

6.Less ethe-ethe kwi-gesi engenayo kunye nokungcola xa kuthelekiswa nezinye iimpompo ezijikelezayo,

7.A isakhiwo eqinileyo, ufakelo lula kunye nokugcinwa.

Ukungancedi kwempompo yokujija kukuba iscrew sifuna ukuqhubekeka okuphezulu kunye nendibano; ukusebenza kwempompo kuluvakalelo kutshintsho kwi-viscosity yolwelo.

Umboniso weMveliso

Iimpazamo eziqhelekileyo kunye nezisombululo

Impompo ayisebenzi:

Izizathu ezinokubakho: I-Rotor kunye ne-stator zixinene kakhulu; ombane iphantsi kakhulu; viscosity le medium liphezulu kakhulu.

Isixazululo: Jikelezisa impompo amaxesha ambalwa ngezixhobo nangabasebenzi, lungisa uxinzelelo; ngxolisa amajelo eendaba.

2. Impompo ayiphumi:

Izizathu ezinokubakho: ujikelezo oluphosakeleyo lokujikeleza; iingxaki ngombhobho wokutsala; viscosity eliphezulu kakhulu eliphakathi; i-Rotor, i-stator, okanye izinto zokuhambisa zonakalisiwe;

Isixazululo: Lungisa indlela ejikelezayo; jonga ukuvuza, indawo yokungena evulekileyo kunye neiveluvu zokuphuma; cola imithombo yeendaba; hlola kwaye ubeke endaweni izinto ezonakeleyo;

3.Ukungahambi:

Izizathu ezinokubakho: imibhobho evuzayo; Izivalo azivulekanga ngokupheleleyo okanye azivalwanga ngokupheleleyo; isantya yokusebenza ephantsi; ukunxiba iirotors kunye nemimiselo.

Isisombululo: Jonga ulungise imibhobho; vula onke amasango, susa iiplagi; lungisa isantya; buyisela iindawo ezonakeleyo

4.Ukungabikho koxinzelelo:

Izizathu ezinokubakho: I-Rotor egugileyo kunye ne-stator.

Isisombululo: Buyisela irotor, i-stator

Ubushushu beMotor:

Izizathu ezinokubakho: ukusilela kwemoto; uxinzelelo oluphuma kakhulu, ukulayishwa kweemoto kunye nomonakalo weemoto. Isisombululo: Jonga imoto kwaye uyisombulule; tshintsha uxinzelelo lohlengahlengiso lokuvula ivalve; buyisela inxenye eyonakeleyo.

Uxinzelelo 6.Flow lehla kabukhali:

Izizathu ezinokubakho: Ukuvaleka ngesiquphe okanye ukuvuza kwesekethe; ukunxiba okunzima kwe-stator; utshintsho ngesiquphe viscosity ulwelo; ukwehla ngesiquphe kwevolthi.

Isixazululo: Susa i-tubing okanye ifakwe uphawu; buyisela irabha ye stator; tshintsha i-viscosity fluid okanye amandla emoto, lungisa i-voltage.

7. Inani elikhulu lolwelo oluvuzayo kwisitywina se-shaft: Oonobangela abanokubakho: Isithambisi sokufaka izinxibo esithambileyo: Cofa okanye ubeke endaweni yento egcwalisiweyo

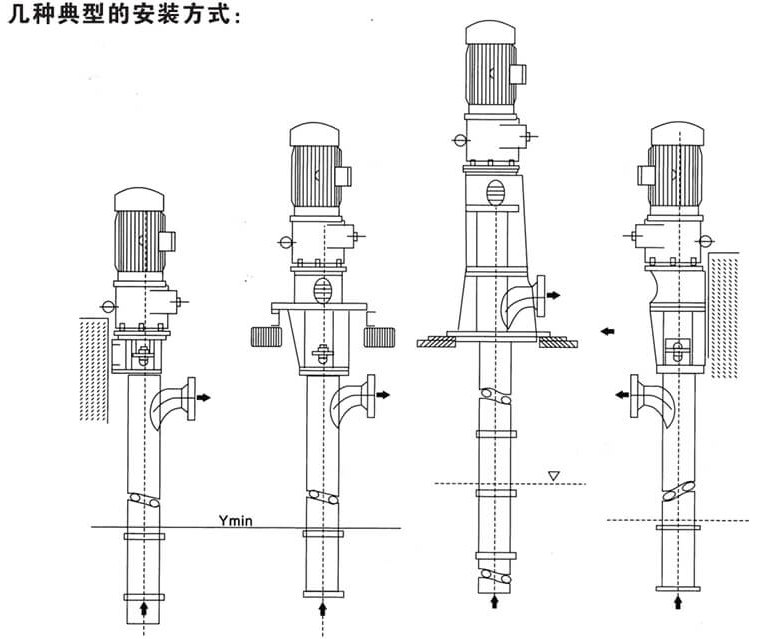

Imiyalelo yokuhlohla

• Nika ingqalelo kwicala lokujikeleza kweemoto ukuthintela ukujikeleza okubuyela umva.

• Umbhobho osusekayo ekulula ukushenxisa isitator kufuneka ufakelwe phambi kokuba kuphume ulwelo ukulungiselela ukutshintshwa kwe stator.

• Gcina indawo yokungena kwimpompo kwicala elithe nkqo, indawo ekuphuma kuyo ethe tyaba, ukuze itywina likwazi ukusebenza kwimeko yoxinzelelo, ukunciphisa uxinzelelo lwegumbi elitywiniweyo. Ujikelezo: ujikeleza ngokuchaseneyo newashi njengoko kubonwe kuphuma. Imibhobho kufuneka imiselwe ukuxhasa amanqaku, kuba ukungena kwempompo kunye neeflet flanges (imibhobho) ayinakumelana nobunzima bombhobho.

• Umbhobho kufuneka ucocwe phambi kokufakwa ukuze kuthintelwe izinto zangaphandle zonakalise i-stator kunye ne-rotor kwaye zibangele ukuvaleka.

• Ubukhulu bepayipi kufuneka bulinganiswe nobubanzi bempompo kangangoko kunokwenzeka. Ububanzi obuncinci be-inlet bubangela ukuba unikezelo olwaneleyo lwempompo, oluya kuchaphazela ukukhutshwa kwempompo kunye noxinzelelo lokuphuma. Kwiimeko ezinzima, kuya kukhokelela ekushukunyisweni kombhobho kunye nomonakalo kwangethuba we-stator. Ububanzi bepayipi encinci kakhulu buya kukhokelela ekuphulukaneni noxinzelelo lweplagi.

• Kwitywina leshafti elinamatywina oomatshini, galela amanzi amatsha, ioyile yokuthambisa, okanye esinye isipholisi.

Ukutywinwa kwamatywina e-shaft aphelelweyo, ukuba ukuhanjiswa okuphakathi kuyinto ebabazekayo, eqinisiweyo ngokulula kunye ne-crystallized medium, itywina elinomatshini kufuneka licocwe emva kokuba impompo iyekile ukusebenza ukuqinisekisa ukusebenza kwesiqinisekiso se-mechanical. Icala ngalinye lebhokisi lokutywina linentambo yombhobho we-intshi, kunye ne-outlet throttlingling ifakiwe. Umgca wokungena wokujikeleza ulwelo uqhagamshele ngqo kwibhokisi yetywina. Kwicala layo lokuphuma, indawo efanelekileyo yokuphuma (ebaluleke kakhulu ekugcineni uxinzelelo oluthile kwibhokisi yokutywina) iyaqhagamshelwa kumgca wokuphuma. Xa ukhangela umatshini enkwenkwezini, ulwelo olujikelezayo kufuneka luqale kuqala, emva koko uvule impompo; xa uyeka, impompo kufuneka imiswe kuqala, emva koko ucime ulwelo olujikelezayo.